Here, we present excerpts from a conversation between Takeshi Tsukamoto, President of KAGA FEI Co., Ltd., and Kenji Suzuki, President of KAGA ELECTRONICS (THAILAND) CO., LTD. (and former President of KAGA EMS TOWADA CO., LTD.), in which they discuss ways they have promoted the Kaga Electronics Group’s unique PMI* as well as their vision for future development of the EMS business.

Investor RelationsInvestor Relations

Investor RelationsInvestor Relations

The Kaga Electronics Group’s Potential for Growth

How KAGA-ism has evolved

* Post-Merger Integration, the integration process following an M&A

Tsukamoto

“Make KAGA FEI a company that embodies the spirit of Kaga Electronics.” These were the words of instruction from President Ryoichi Kado when I was assuming the position of Managing Director. KAGA FEI, or Fujitsu Electronics as it was known prior to its acquisition, was a trading company under the umbrella of the Fujitsu Group, an entity much larger than Kaga Electronics alone. At the time, I knew it would have been pointless to simply adopt Kaga Electronics’ style of “just charging ahead” like a rogue samurai. I believed my role was to preserve KAGA FEI’s strengths while also adopting the Company’s distinctive spirit of embracing challenges and mindset of thoroughly hedging its risks.

Prior to taking my first meeting in January 2019, I told my staff to prepare themselves for the long haul as we would be visiting every Group location over the course of the year. True to my word, I visited every domestic and international location, starting with the Shizuoka Sales Office that February and ending with a visit to South Korea on Christmas Eve.

We began the PMI process with an eye toward building a company that embodies the Kaga Electronics spirit. However, the COVID-19 pandemic struck the following year, leaving us unable to move about freely. Looking back, being able to visit each and every location during my first year as Managing Director was a stroke of good fortune.

After the acquisition went into effect, KAGA FEI faced a series of events that shook the Company to its core. However, we were able to seize those crises as opportunities, transforming ourselves into a company that truly embodies the spirit of Kaga Electronics.

The first such event was a steep decline in sales, which stood at approximately ¥230 billion at the time of acquisition, to about ¥130 billion the following year. This was the result of losing the commercial rights of a major supplier around the time the former parent company underwent business restructuring. We responded by kicking the search for new vendors into high gear. Thanks to KAGA FEI’s technical team of over 200 discerning experts and their exceptional ability to identify high-quality vendors, the search was an overall success.

In fact, we receive so many eager requests from those who want to put their products on the market through us, confident that they will sell well, that I’ve had to step in to slow things down. Next came the COVID-19 pandemic and the subsequent semiconductor shortage. This left us completely unable to procure goods through our regular channels. At the time, we had to engage in spot sales, in which we sold whatever scarce parts we were able to procure from the market.

Next came the COVID-19 pandemic and the subsequent semiconductor shortage. This left us completely unable to procure goods through our regular channels. At the time, we had to engage in spot sales, in which we sold whatever scarce parts we were able to procure from the market.

Initially, I was uncertain if KAGA FEI was even able to engage in spot sales. When I asked, I was told that it was general good practice to not handle any products with unknown serial numbers or inventory already on the market. As our customers were also struggling amid the parts shortage, I gave the order to allow spot sales as long as all transactions were made with customers’ full acknowledge and consent regarding the uncertainties involved. We received a wave of orders not long after.

Compared to Kaga Electronics, KAGA FEI’s existing customers have vastly larger purchasing volumes, meaning that this approach alone generated billions of yen in new sales. Moreover, we were able to leverage our advantage by taking a technical approach from the start and maintaining a presence in customers’ design and development departments, giving us insight into where there may be insufficiencies, receiving information directly from procurement departments charged with sourcing parts and even the design and development departments themselves. Leveraging our expertise in technology proved to be a key factor in our business expansion and deepened our involvement in not only the procurement of parts, but also our clients’ design and development stages.

Seeing customers so pleased, sales and profits growing, and even receiving year-end bonuses fostered a mindset that permeated our company; as an independent trading firm, we could sell anything. Cross-selling Kaga Electronics Group products through KAGA FEI also increased, becoming a positive catalyst for greater Groupwide integration. At the time of acquisition, 95% of KAGA FEI’s sales were Fujitsu or Fujitsu Group products, but this year approximately half of total sales are expected to come from products sourced from suppliers engaged with after the acquisition.

Suzuki

Prior to becoming a Group company, KAGA EMS TOWADA (hereinafter TOWADA), operated under the name Towada Pioneer Corporation and functioned as a regional satellite factory or branch plant for then-parent company Pioneer Corporation. There were significant differences in Pioneer’s and Kaga Electronics’ corporate culture, business practices, and approaches.

First, in terms of culture, we focused on instilling in TOWADA employees the three main pillars of KAGA-ism—a management mindset, a sales mindset, and readiness as members of society—placing particular emphasis on embedding the ability to think and act independently and work toward self-improvement. We provided step-by-step guidance, using a consultative approach to illustrate specific and concrete examples.

In terms of business practices and approaches, TOWADA lacked expertise related to product planning and development, sales, and material procurement functions, as it had been operating as a downstream manufacturing facility for its parent company. One of the strengths of Kaga Electronics’ EMS business, on the other hand, is its independent profit and loss system. In other words, each Group company operates independently, conducting its own sales and manufacturing its own products. This meant that after the merger, there were gaps to fill throughout the business process.

Our first step was to create manuals for such upstream processes as business strategy, sales and negotiations, and the preparation of quotations, and work to standardize them. From there, we established our own business divisions by selecting staff from our manufacturing department and instilling in them our action guideline F.Y.T. (FLEXIBILITY, YOUNG, TRY). At the same time, we selected suitable candidates, trained them in the fundamentals of procurement, and established a purchasing department by adapting manuals from Kaga Electronics.

Over the span of one to two years, we transformed and integrated a new mindset into our business processes, namely, one that embraces our capability to independently handle sales, secure orders, manufacture products, and turn a profit as well as the idea that we will ultimately see returns on our investments.

The Kaga Electronics Group’s EMS business originally started with the aim of supporting the overseas shift of Japanese manufacturing, so its manufacturing bases are primarily overseas. However, about five years ago, international circumstances, particularly geopolitical issues, prompted a movement toward reshoring manufacturing. This necessitated the creation of domestic manufacturing bases for Kaga Electronics as well, leading to the acquisition of TOWADA in October 2019. As a result, TOWADA is the latest addition to the global factory network of the Group’s EMS business.

Against this backdrop, we have made extensive use of the Kaga Electronics Group’s sales capabilities and parts procurement strength. Since TOWADA’s inception, we have pursued a collaborative business model with KAGA FEI, in which KAGA FEI handles sales and product planning and design while TOWADA undertakes manufacturing once an order is secured. In this way, TOWADA operates independently and has access to sales and procurement functions, thereby leveraging the strength of the Group.

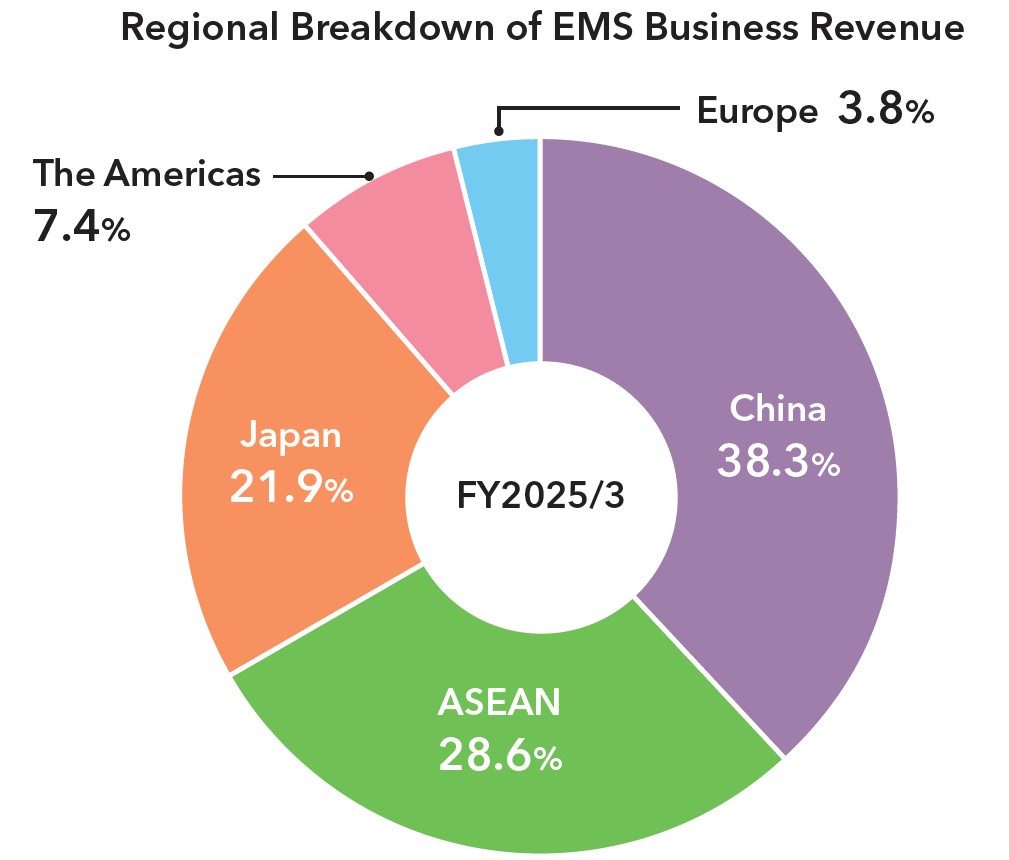

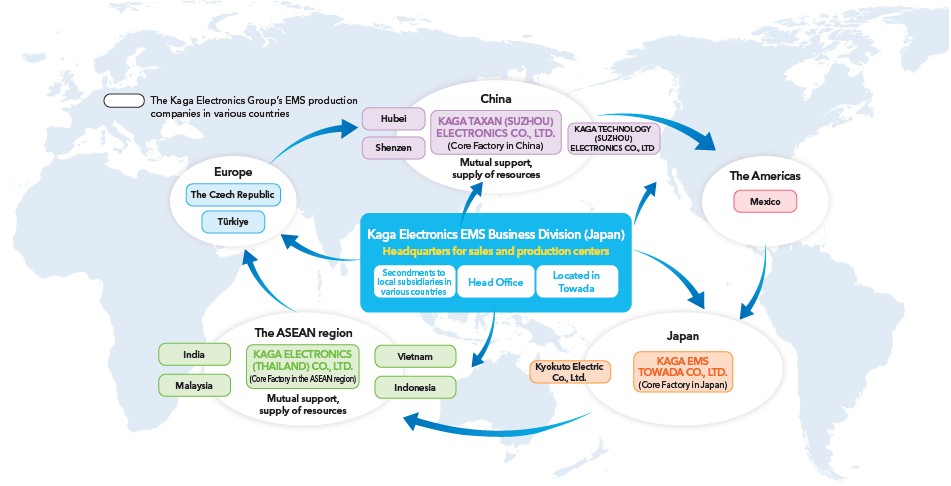

Until recently, TOWADA served as the mother factory for the entire EMS business. However, manufacturing operations that have shifted overseas are moving away from China toward the ASEAN region, which is gaining importance as a production hub. Accordingly, starting this fiscal year, we have transitioned to a “three-site system," with the three core sites being TOWADA, KAGA TAXAN (SUZHOU) in China, and KAGA ELECTRONICS (THAILAND).

Based in Japan, TOWADA handles intellectual property functions such as overall quality control and manufacturing know-how. Our bases in Suzhou, China, possess both extensive experience in mass production and the strength necessary to develop their own automation equipment. By refining their approach to creating cost-effective production equipment and tailoring it to the Group’s needs, these facilities will fulfill their role in leveraging automation equipment across the entire Group.

The Thai base will serve as our manufacturing hub within the ASEAN region, attracting new customers and expanding production to meet emerging needs driven by trends such as BCP and the shift away from China. This three-site system is designed to support the further evolution of the Kaga Electronics Group’s EMS business.

Toward the Further Growth of the EMS Business

Suzuki

The Kaga Electronics Group is unique in that although it started as an electronic components trading company, it has since expanded, growing from parts procurement and kitting operations to post-processing circuit board mounting and the assembly of finished products. Bringing KAGA FEI into the fold added design and development capabilities. With that said, we take great pride in being the ultimate behind-the-scenes team supporting our customers’ monozukuri, or manufacturing, endeavors.

Looking at the timeline, while we began outsourcing processing to domestic partner factories in the 1970s, it wasn’t until 1992 that we secured our first regional foothold in Hong Kong and initiated similar operations in China. In 1999, Kaga Electronics launched KAGA (SHENZHEN) ELECTRONICS LTD., its first Company-owned overseas factory. We have since expanded into Malaysia (2000), Thailand (2002), the Czech Republic (2009), Suzhou, China (2009), Indonesia (2014), Hubei, China (2015), Mexico (2017), Vietnam (2017), Turkey (2018), India (2018), Aomori Prefecture (2019), and Tottori Prefecture (2020). We now operate in 21 locations across 10 countries worldwide.

Guided by our corporate philosophy, “Everything we do is for our customers,” we have swiftly and deliberately established overseas bases in countries and regions where our customers are expanding their production activities. This has not only enabled us to create a framework that provides locally sourced and utilized solutions that are tailored to our customers’ needs, but also to expand our business sphere beyond Japanese corporations.

While there are many other semiconductor trading companies, Kaga Electronics has drawn particular recognition as a pioneer of the EMS business, which was developed within its own factories, as well as for maintaining the industry’s largest EMS network. Kaga Electronics is one of the few EMS specialists in the industry, with sufficient electronic component trading capabilities enabling the offering of services that integrate the strengths of both EMS operations and electronic components trading. The Group’s EMS business excels thanks to the wide range it can supply in a variety of production quantities. We do this through the provision of a “convenience store-type” of EMS that offers proximity and convenience for customers

through high-mix, low-volume production and a “General Merchandise Store (GMS)-type” of EMS providing medium-scale production where customers can find most items nearby and make bulk purchases. These capabilities distinguish us from competitors

that employ the “Taiwanese/Asian Mega EMS” model, which focuses more on mass production and, like a suburban shopping center, relies on quantity over quality.

Suzuki

Let’s dive in a bit deeper into the previously mentioned “three-site system.”

We established SUZHOU HATTEN INTELIGENT EQUIPMENT CO., LTD. a joint company between an equipment manufacturer in Suzhou and KAGA ELECTRONICS that independently develops such equipment as solder baths, surface mount machines, and various inspection machines—all of which are tailored to match our own production lines. This company’s strengths lie in the way it develops in-house equipment that reduces labor and streamlines processes that require significant manpower.

Equipment developed in-house is first introduced in China or Thailand as the vanguard and then to other locations one after the other. In other words, our factories in Suzhou and Thailand serve as the pilots and operational models for our proprietary equipment.

KAGA ELECTRONICS (THAILAND), where I currently serve as president, is the Kaga Electronics Group’s largest manufacturing base in terms of production area and number of employees. This company’s strength lies in its capability to accommodate the needs of customers in such diverse fields as the automotive industry, air conditioning, factory automation, and consumer electronics. Of our two factories, one specializes in automotive applications, while the other focuses on office automation equipment such as wireless modules, copiers, and devices for operating systems. A third factory is currently under construction and this facility will fully implement factory automation with the goal of thoroughly reducing the need for labor. Until recently, each manufacturing site was tasked with handling specific product lines within its capabilities. KAGA ELECTRONICS (THAILAND), however, will be positioned as a factory capable of handling products across all fields.

While Thailand is currently our largest sales market, we anticipate Mexico will take that position in the next three to four years.

In April 2024, our factory in Mexico, established in 2017, completed its relocation from its original building (land area: 23,000 m²; floor area: 8,200 m²) to a new factory (land area: 80,000 m²; floor area of Phase 1 (completed) 20,000 m², Phase 2 (planned) 20,000 m²). This facility introduced equipment featuring the latest automation, labor-saving, and energy-saving technologies. Phase 1 has launched operations for circuit board mounting and unit assembly with plans to expand to a fully integrated production system encompassing parts molding, sheet metal processing, and final product assembly. Under our five-year plan, we aim to increase net sales to ¥50 billion and create 2,000 jobs.

Alongside Mexico, Malaysia is another location where we seek horizontal expansion. Bordering Thailand, Malaysia boasts high production volumes and a large workforce. Here, the entire production process is split into two stages: the front-end, where

machines handle component assembly, and the back-end, where the final assembly is performed by our employees. In Malaysia, the back-end stage accounts for a large portion of overall processing, highlighting the issue of a workforce that’s disproportionately large compared to production volume. This is why we will advance our efforts to automate processes and thereby reduce labor.

The strength of our domestic bases lies in their ingenuity and flexibility underpinned by a high-quality production system. Our locations in Japan play a key role in leading the advancement of monozukuri through the standardization of high-quality production methods and equipment innovation. In addition, they ensure that these achievements are shared with overseas bases.

Suzuki

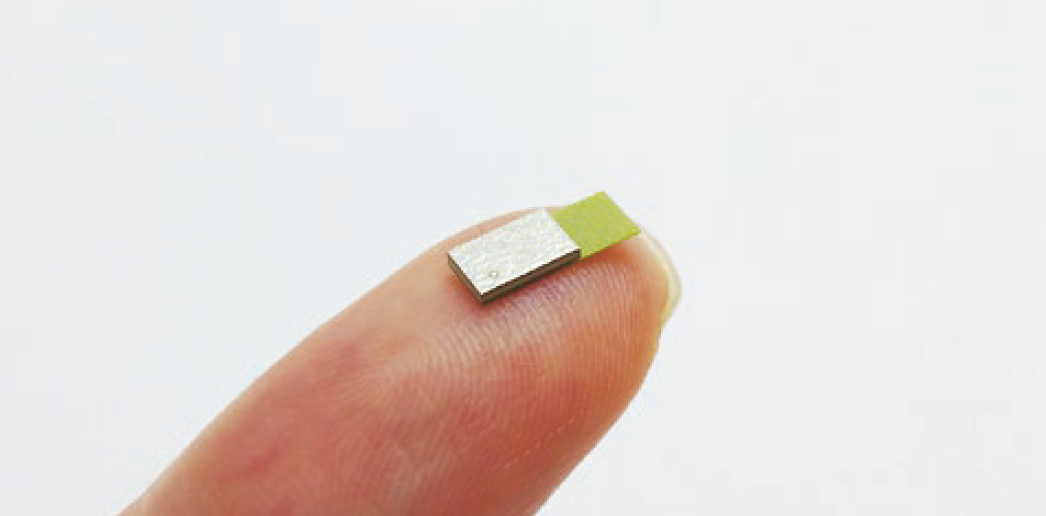

In 2022, KAGA FEI acquired the rights of a small wireless module business from TAIYO YUDEN CO., LTD., taking over not only its sales but the product planning, development, and design operations handled by its development center. Today, the production process is split between TOWADA and KAGA ELECTRONICS (THAILAND), achieving 100% in-house production.

This is a prime example of our previously mentioned collaboration with KAGA FEI. For actual manufacturing, we are introducing in-house developed equipment to enhance cost competitiveness. From a Group perspective, this can be seen as a high-value-added business that transcends the realm of trading companies or EMS providers, operating as a component manufacturer that integrates development, manufacturing, and sales.

Tsukamoto

As Taiyo Yuden had previously acquired some of Fujitsu’s wireless technology, when considering potential business transfer partners, KAGA FEI was the first company to be approached. After that, our first step was to conduct inspections of its Japan and Thailand locations, through which we discovered that the necessary equipment relocation to TOWADA and KAGA ELECTRONICS (THAILAND) would require minimal capital investment. We also realized that by leveraging the Kaga Electronics Group’s procurement capabilities, we could potentially further reduce manufacturing costs.

Suzuki

Initially, our production transfer approach involved replicating their existing manufacturing process. Although the equipment at the disposal of TOWADA and KAGA ELECTRONICS (THAILAND) was similar, allowing the use of most of our own machinery, we lacked vital new and specialized equipment. Therefore, adjustments had to be made so that we could work with differing specifications between equipment types, posing a real challenge to the idea of a smooth transfer while minimizing costs.

After numerous trial production cycles, we managed to finish our preparations for mass production in the span of roughly a year and three months.

Tsukamoto

Our business strategy does not include targeting the low-price product market pursued by competitors in China and Taiwan. Providing customers with such competitive products as the world’s smallest ultra-compact devices and solutions that support long-distance communication is what sets us apart. In addition, KAGA FEI is able to support customers’ efforts to obtain radio certification in various countries.

As a result, KAGA FEI’s customers are able to create wireless products by adopting our modules without having to do anything in-house. This enables even customers without previous expertise in electronics or electronic components to produce numerous wireless products with communication functions and represents a significant business opportunity for KAGA FEI.

This endeavor won’t just apply to individual modules, but also to the assembly of the printed circuit boards on which they are mounted. Directly assembling the boards for our customers’ products on TOWADA and KAGA ELECTRONICS (THAILAND) assembly lines, where the modules are also produced, will help shorten the manufacturing process for our customers. This enhances the KAGA FEI’s added value associated with circuit boards, including material and component costs, processing fees, and more.

Only the Kaga Electronics Group is capable of achieving such a feat as it combines its functions as an electronics component trading company with those of an EMS manufacturer.

We look forward to your continued support as we pursue future earnings growth.